- Dongguan NHF Machinery Co., Ltd.

- francesgu1225@hotmail.com

- +8618689452274

✧ Advanced Technology

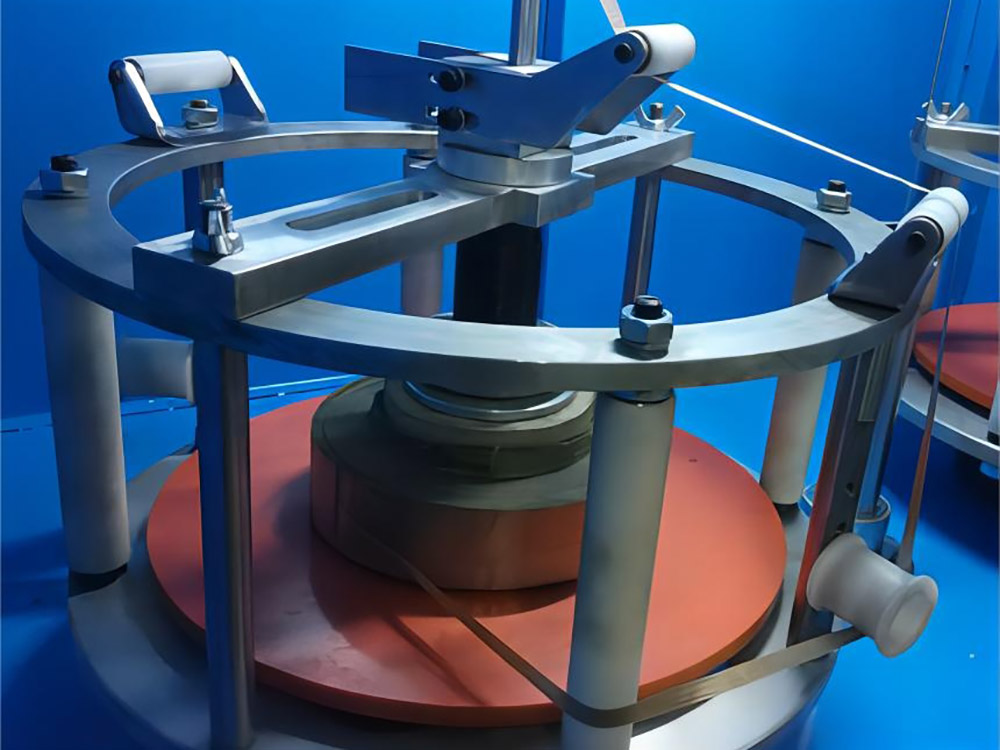

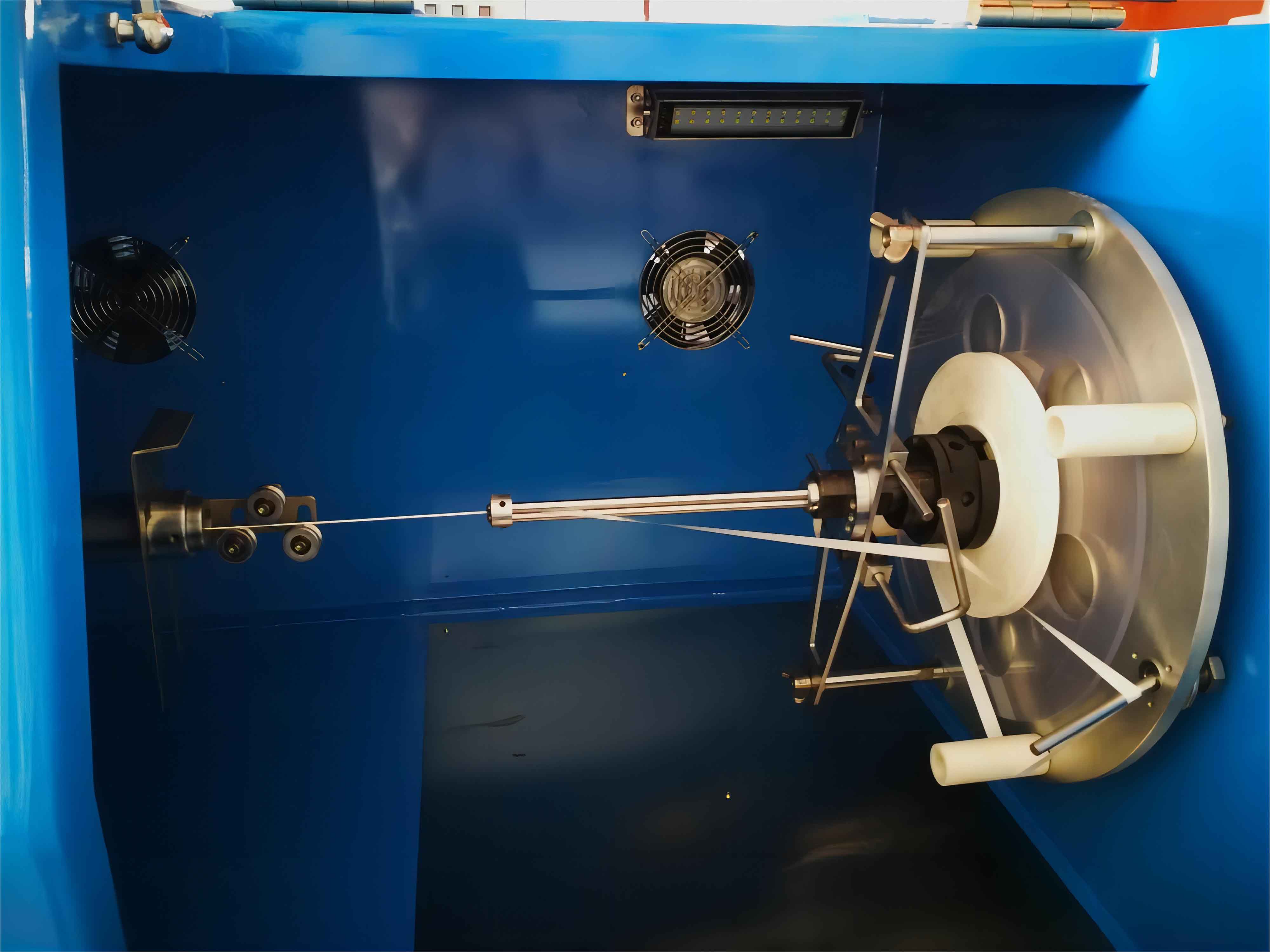

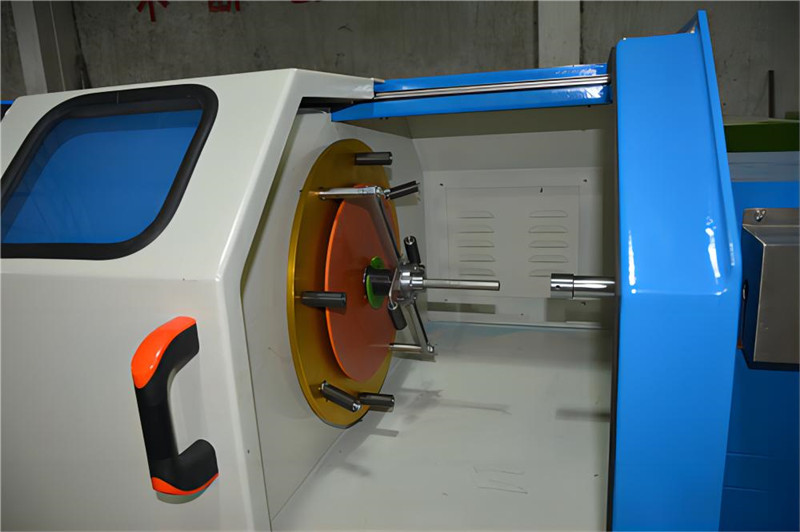

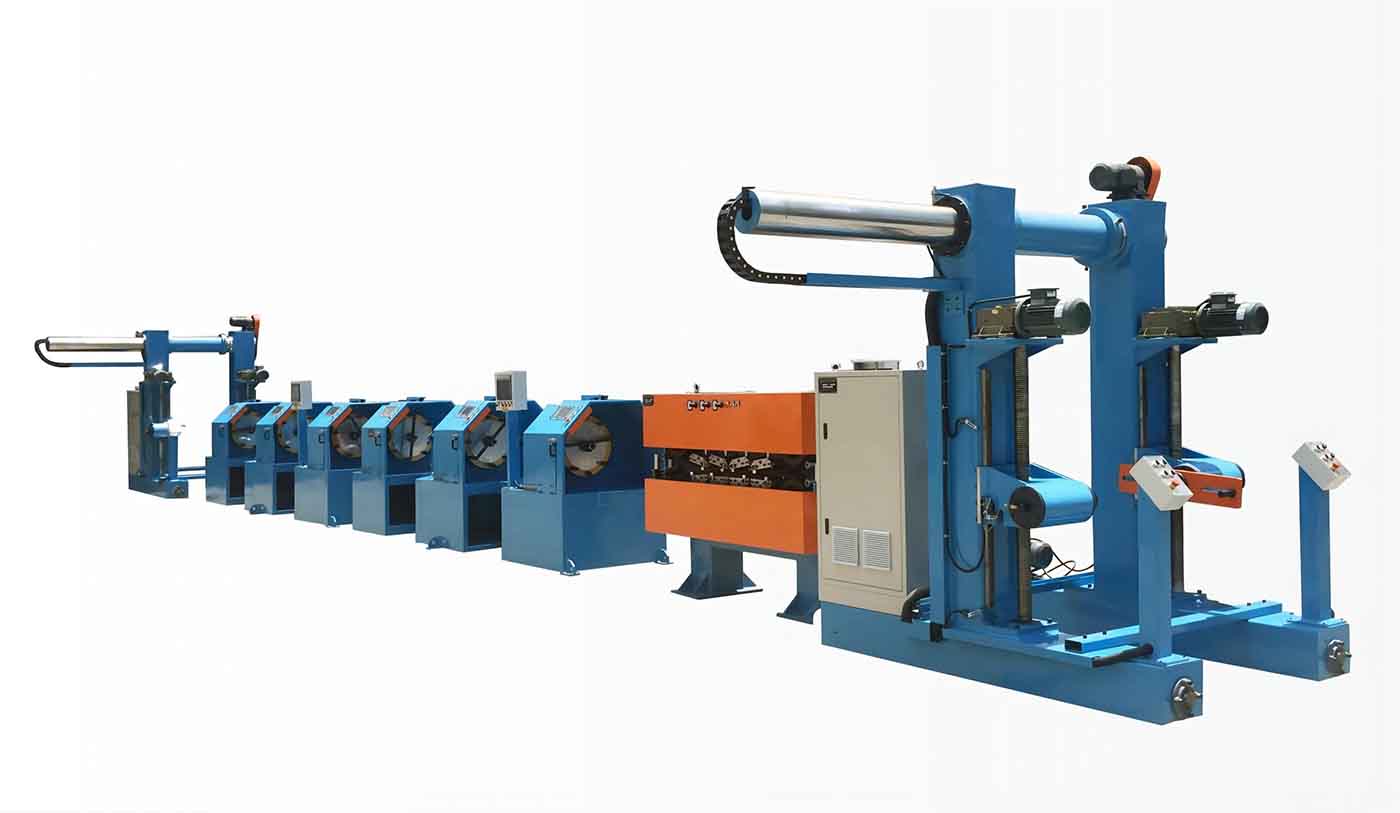

The Piece Type Vertical Concentric Taping Machine is a state-of-the-art taping machine that utilizes advanced technology to provide the best possible results. With its innovative design, this machine is capable of producing high-quality concentric taping for a variety of applications. The machine is equipped with advanced sensors and controls that ensure precise and consistent taping, even at high speeds.

✧ High Performance

The Piece Type Vertical Concentric Taping Machine is designed for high performance. It is capable of taping a wide range of materials, including wires, cables, and hoses, with a high level of accuracy and consistency. The machine is also designed to operate at high speeds, which makes it ideal for high-volume production environments. With its high-performance capabilities, the Piece Type Vertical Concentric Taping Machine is the perfect choice for businesses that demand the best.

✧ Multifunctionality

The Piece Type Vertical Concentric Taping Machine is a multi-functional machine that is capable of performing a variety of taping operations. It can be used for concentric taping, spiral taping, and even for applying insulation materials. The machine is also equipped with a variety of accessories that allow it to be customized to meet specific production needs. With its multi-functional capabilities, the Piece Type Vertical Concentric Taping Machine is a versatile machine that can be used in a variety of applications.

✧ Reliability

The Piece Type Vertical Concentric Taping Machine is a reliable machine that is built to last. It is constructed from high-quality materials and is designed to withstand the rigors of daily use. The machine is also equipped with advanced safety features that ensure safe operation. With its reliable performance, the Piece Type Vertical Concentric Taping Machine is the perfect choice for businesses that demand high-quality and reliable equipment.

✧ Conclusion

In conclusion, the Piece Type Vertical Concentric Taping Machine is the ultimate solution for your taping needs. With its advanced technology, high performance, multi-functionality, and reliability, this machine is the perfect choice for businesses that demand the best. Whether you need to tape wires, cables, or hoses, the Piece Type Vertical Concentric Taping Machine is the perfect choice for your production needs. So why wait? Contact us today to learn more about this amazing machine and how it can benefit your business.

Technical Specifications

|

Machine model |

BZ500Z syetem setting computer preset pitch |

| Packing material |

Aluminum foil tape,Mylar tape, cotton paper tape,transparent tape,mica tape, Teflon tape,maximum width60mm |

| Cable diameter |

φ4~30mm |

| Spinning speed |

2200 rpm |

| Production line speed |

50M/min Max. |

| Tension control |

Magnetic powder tension, servo tension |

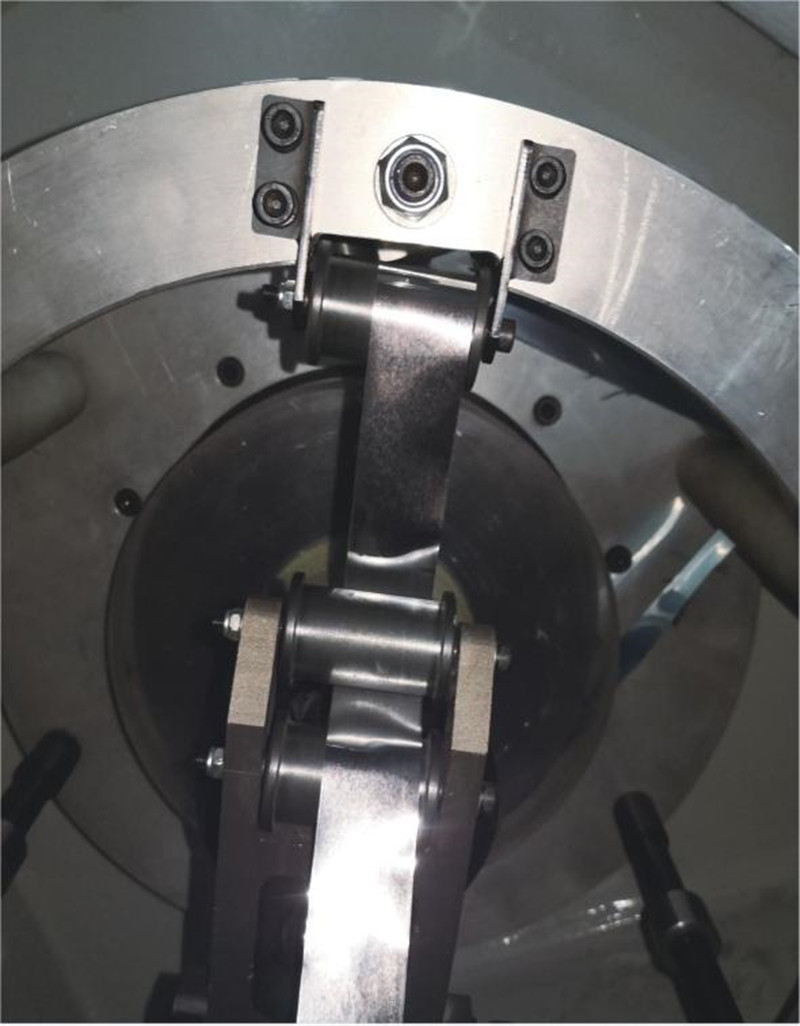

| Pitch control |

Digital setting, closed loop control |

| Take-up method |

Torque mode take-up |

Characteristics

Suitable for HDMl, Display port, USB3.0, USB3.1, SATA, copper conductor and insulating core wire or sheath cable continuous multilayer (or single) centers around the package.

Materials: Aluminum foil, transparent, mica tape, imine belt, cotton, Teflon tape.

Process

Welding

Polish

Machining

Boring Mill

Assembling

Finished Product

FAQ

A: Yes, we do the following:

-Once the customer informs us that the machine is placed in the correct position, we will send mechanical and electrical engineers to start the machine.

-No-load test: After the machine is completely installed, we first carry out the no-load test.

-Load test: Usually we can produce three different wires for load test.

A: We will conduct dynamic balance test, levelness test, noise test, etc. In the production process.

After the completion of production, we usually carry out no-load operation on each machine before delivery. Welcome customers to visit.

A: We have an international universal color card RAL color card. You just need to tell us the color number. You can customize your machine to match the color matching of your factory.

Answer: Of course, this is our purpose. According to the standards that your cable should follow and your expected productivity, we will design all the equipment, molds, accessories, personnel, inputs and required materials to make documents for you.