Introduction to NHF and Extrusion Machinery

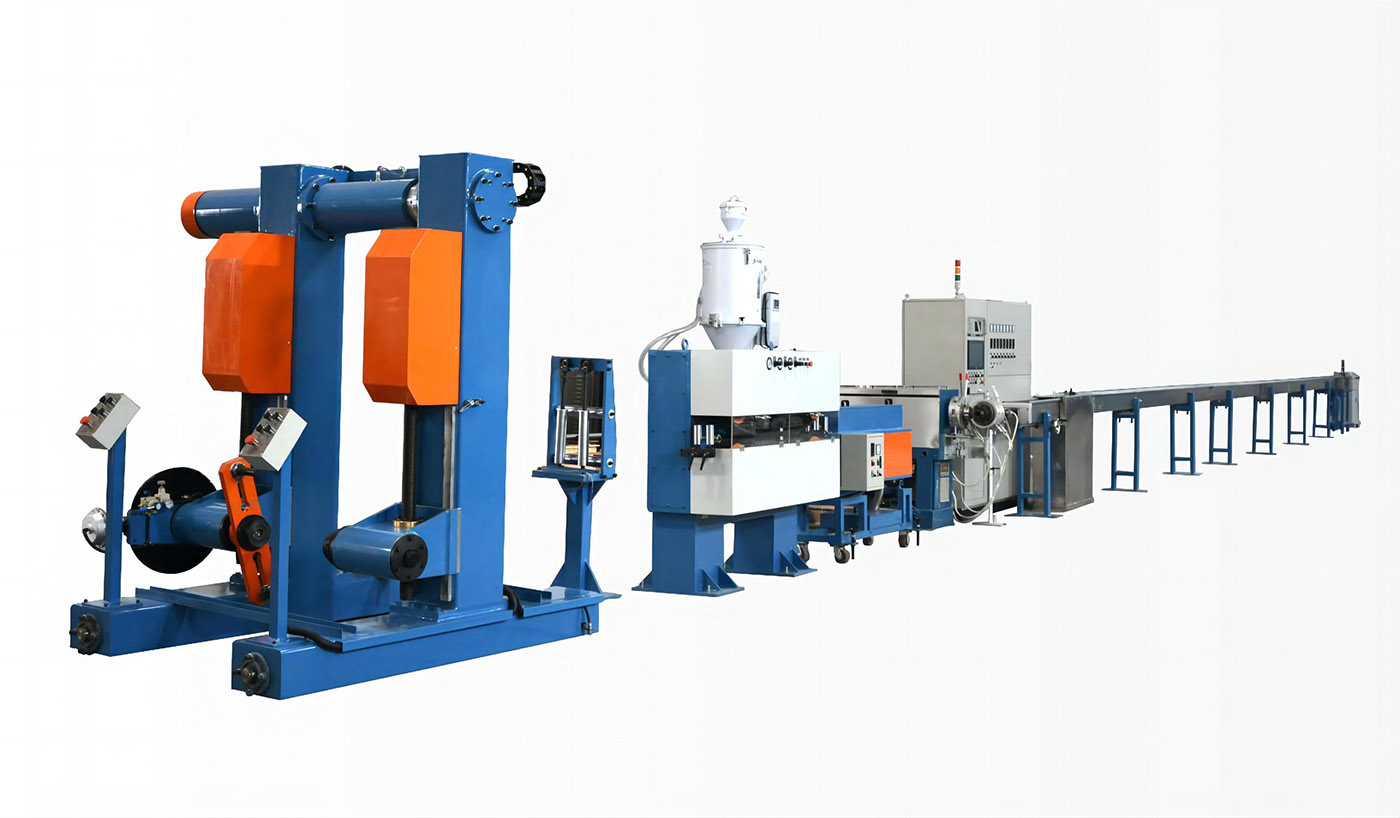

Dongguan NHF Machinery Co., Ltd (NHF) is a leading name in the manufacturing industry, specializing in extrusion machinery that has revolutionized mass production processes. With cutting-edge technology and innovative designs, NHF has positioned itself as a key player in enhancing production efficiency for industries worldwide. Extrusion machinery plays a pivotal role in shaping raw materials into desired forms, making it indispensable for sectors such as construction, automotive, and consumer goods.

Understanding Extrusion Machinery

Extrusion machinery is a manufacturing tool used to transform materials, typically plastics, metals, or rubber, into specific profiles or shapes. The process involves pushing material through a die to create objects with a uniform cross-section. NHF’s extrusion machinery is engineered to deliver precision, consistency, and speed, making it ideal for mass production applications.

Chemical foaming extruder

Silicone cable extruder

Electronic wire extruder

Fluoroplastic extruder

One of the key features of NHF’s machinery is its ability to handle various materials while maintaining high output rates. This versatility ensures that manufacturers can meet diverse market demands without compromising on quality. Additionally, NHF’s focus on energy-efficient designs helps reduce operational costs, further amplifying its appeal to industries aiming for sustainable production practices.

Mass Production Efficiency: A Game Changer

Mass production efficiency is critical for industries looking to scale operations without inflating costs. NHF’s extrusion machinery has been instrumental in achieving this goal by streamlining production processes and minimizing waste. The machinery is designed to operate continuously, ensuring uninterrupted production cycles and reducing downtime.

Moreover, NHF’s advanced automation systems enable manufacturers to monitor and control production parameters with precision. This reduces human error and enhances overall productivity. With NHF’s extrusion machinery, companies can achieve faster turnaround times, meet tight deadlines, and maintain consistent product quality.

Key Benefits of NHF Extrusion Machinery

- Enhanced Productivity: NHF’s machinery allows for high-speed production, ensuring that manufacturers can meet growing market demands efficiently.

- Material Versatility: The ability to process a wide range of materials makes NHF’s extrusion machines suitable for diverse industries.

- Energy Efficiency: NHF’s focus on sustainable designs helps reduce energy consumption, lowering operational costs and environmental impact.

- Precision and Consistency: Advanced technology ensures that products are manufactured with uniform quality and dimensions.

- Reduced Waste: Optimized processes minimize material wastage, contributing to cost savings and eco-friendly production.

Industry Applications

NHF’s extrusion machinery has found applications across a wide range of industries. In the construction sector, it is used to produce pipes, profiles, and insulation materials. The automotive industry benefits from NHF’s machinery in manufacturing components such as seals, gaskets, and tubing. Additionally, consumer goods manufacturers rely on extrusion machinery for creating packaging materials, containers, and household items.

The versatility of NHF’s machinery ensures that it can adapt to the specific needs of each industry. For instance, the machinery can be customized to handle high-strength materials for automotive applications or lightweight materials for packaging solutions. This adaptability makes NHF a preferred choice for manufacturers looking to optimize their production processes.

Latest Innovations by NHF

NHF continuously invests in research and development to stay ahead in the competitive market. Recent innovations include the integration of IoT technology into extrusion machinery, enabling real-time monitoring and predictive maintenance. This not only enhances operational efficiency but also reduces the risk of unexpected breakdowns.

Another noteworthy development is NHF’s focus on eco-friendly designs. The company has introduced machinery that uses biodegradable materials, catering to the growing demand for sustainable production practices. These innovations underline NHF’s commitment to driving progress in the manufacturing industry.

Challenges and Solutions

While extrusion machinery offers numerous benefits, manufacturers often face challenges such as high initial investment costs and the need for skilled operators. NHF addresses these issues by providing comprehensive training programs and after-sales support to ensure that clients can maximize the potential of their machinery.

Additionally, NHF offers flexible financing options to make its machinery accessible to businesses of all sizes. This approach has helped the company build long-lasting relationships with its clients and establish itself as a trusted partner in the manufacturing sector.

Conclusion

Dongguan NHF Machinery Co., Ltd has undoubtedly transformed the landscape of mass production with its state-of-the-art extrusion machinery. By prioritizing efficiency, sustainability, and innovation, NHF has set new benchmarks for the manufacturing industry. Whether it’s enhancing productivity or reducing environmental impact, NHF’s machinery is a testament to the company’s commitment to excellence.

As industries continue to evolve, the demand for reliable and efficient production solutions will only grow. With its forward-thinking approach and dedication to quality, NHF is well-equipped to meet these challenges and drive the future of manufacturing.

Post time: Jul-07-2025