Introduction to NHF and Its Double Twist Bunching Machines

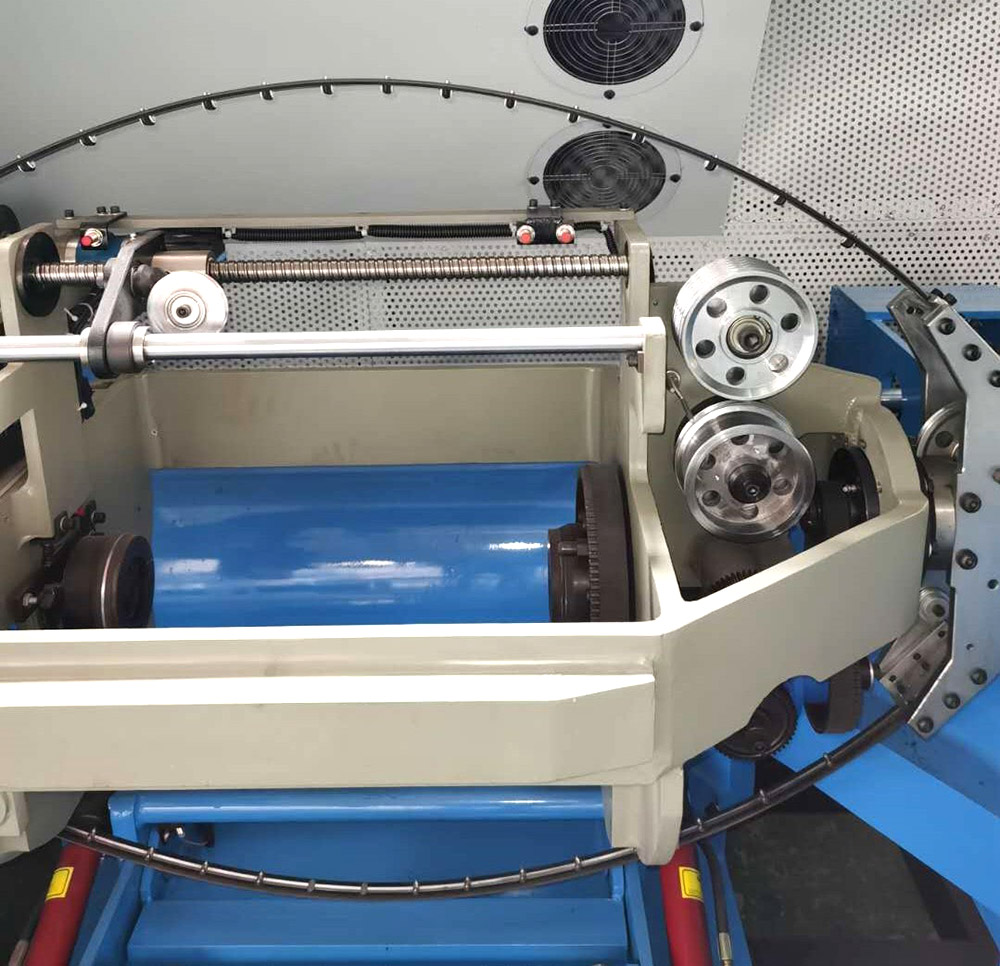

Dongguan NHF Machinery Co., Ltd (NHF) is a renowned name in the wire and cable manufacturing industry. With years of expertise and innovation-driven practices, NHF specializes in producing high-quality machinery that revolutionizes cable production processes. Among its flagship products is the Double Twist Bunching Machine, which has become a cornerstone for modern cable production efficiency.

In today’s fast-paced manufacturing environment, efficiency and precision are paramount. NHF’s Double Twist Bunching Machines are designed to address these needs by offering state-of-the-art technology and robust performance. But how exactly does NHF enhance cable production efficiency through its machinery? Let’s explore.

Understanding Double Twist Bunching Technology

Double Twist Bunching Machines are essential for creating finely twisted wire bundles, which are integral to producing high-quality cables. These machines twist multiple strands of wire together to form a cohesive, durable cable core. The double twist mechanism ensures uniformity, strength, and flexibility in the finished product, which is critical for applications like telecommunications, automotive wiring, and power transmission.

NHF’s Double Twist Bunching Machines stand out in the industry due to their advanced engineering and innovative features. These machines are equipped with cutting-edge components that ensure smooth operation, minimal downtime, and unparalleled precision.

Key Features of NHF Double Twist Bunching Machines

- High-Speed Operation: NHF machines are designed to operate at exceptional speeds, significantly reducing production time while maintaining quality.

- Energy Efficiency: NHF prioritizes sustainability by incorporating energy-efficient mechanisms that lower power consumption.

- Durability: Built with premium-grade materials, NHF machines are engineered for long-term reliability and minimal maintenance.

- Flexibility: The machines are adaptable to various wire types and sizes, making them suitable for diverse production needs.

Enhancing Production Efficiency with NHF Machinery

Efficiency in cable production is not just about speed; it encompasses quality, consistency, and cost-effectiveness. NHF’s Double Twist Bunching Machines address these aspects comprehensively, enabling manufacturers to achieve superior results. Here’s how:

Optimized Workflow

NHF machines streamline the cable manufacturing process by integrating multiple functions into a single operation. The double twist mechanism eliminates the need for additional processes, reducing labor costs and production time. This optimized workflow allows manufacturers to scale their operations without compromising quality.

Precision and Consistency

One of the standout features of NHF’s Double Twist Bunching Machines is their ability to deliver consistent results. The advanced control systems ensure uniform twisting of wires, which is crucial for maintaining the integrity of the cables. This precision minimizes defects and enhances the overall reliability of the finished product.

Cost Savings

By reducing energy consumption and minimizing material wastage, NHF machines contribute to significant cost savings. Additionally, their durable construction and low maintenance requirements further reduce operational expenses, making them a cost-effective choice for manufacturers.

Industry Trends and NHF’s Role

The global wire and cable industry is evolving rapidly, driven by technological advancements and increasing demand for high-performance cables. As industries like telecommunications, automotive, and renewable energy continue to expand, the need for efficient cable production machinery becomes more critical.

NHF is at the forefront of this evolution, consistently innovating to meet the changing demands of the industry. By investing in research and development, NHF ensures its machinery remains ahead of the curve, offering solutions that align with emerging trends.

Impact of Automation in Cable Manufacturing

Automation is reshaping the cable manufacturing landscape, and NHF is playing a pivotal role in this transformation. The integration of automated systems in NHF’s Double Twist Bunching Machines enhances productivity, reduces human error, and ensures consistent quality. This shift towards automation is helping manufacturers meet the growing demand for high-quality cables while maintaining competitive pricing.

Focus on Sustainability

Sustainability is another key trend in the industry, with manufacturers seeking eco-friendly solutions to reduce their environmental impact. NHF addresses this need by designing energy-efficient machinery that minimizes power consumption and material wastage. By prioritizing sustainability, NHF is helping manufacturers align with global environmental goals.

Conclusion

Dongguan NHF Machinery Co., Ltd (NHF) has established itself as a leader in the wire and cable manufacturing industry by delivering innovative solutions that enhance production efficiency. Its Double Twist Bunching Machines exemplify the company’s commitment to quality, precision, and sustainability.

By optimizing workflows, ensuring consistent results, and reducing operational costs, NHF machinery empowers manufacturers to stay competitive in a rapidly evolving industry. As trends like automation and sustainability continue to shape the market, NHF remains dedicated to driving progress and setting new benchmarks for excellence.

Whether you’re a seasoned manufacturer or a newcomer to the industry, NHF’s Double Twist Bunching Machines offer the perfect blend of performance, reliability, and efficiency to elevate your cable production capabilities.

Tags:Extruder Machine,Coiling Machine

Post time: Jun-03-2025