Introduction to NHF and Its Role in Cable Stranding Innovation

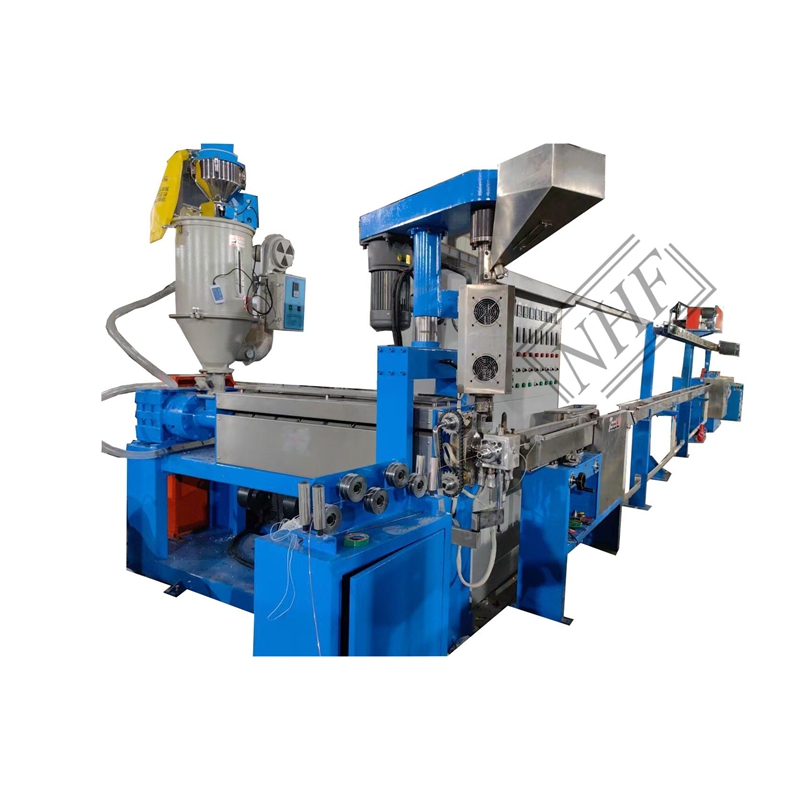

Dongguan NHF Machinery Co., Ltd, widely known as NHF, has emerged as a leading force in the cable manufacturing industry. Specializing in cutting-edge cable Stranding Machines, NHF is setting new benchmarks for efficiency, precision, and scalability in manufacturing. The company’s innovative solutions are driving significant advancements in industries reliant on high-quality cables, such as telecommunications, automotive, aerospace, and energy.

As global demand for advanced cables continues to grow, NHF’s cable stranding machines are playing a pivotal role in meeting these needs. By leveraging state-of-the-art technology and a commitment to quality, NHF is revolutionizing the way cables are manufactured in China and beyond.

The Importance of Cable Stranding Technology

Cable stranding is a crucial step in the manufacturing process of electrical and communication cables. It involves twisting multiple strands of wire together to form a single, cohesive cable. This process enhances the cable’s durability, flexibility, and conductivity, making it suitable for a wide range of applications. NHF’s cable stranding machines are designed to optimize this process, ensuring consistent quality and high production volumes.

Traditional cable manufacturing methods often struggle to meet the demands of modern industries. NHF’s innovative approach addresses these challenges by integrating advanced automation and precision engineering into its machines. This not only improves production efficiency but also reduces material waste and operational costs.

Key Features of NHF Cable Stranding Machines

- High Precision: NHF machines are equipped with advanced sensors and control systems that ensure precise stranding of wires.

- Automation: Automated processes reduce the need for manual intervention, minimizing errors and improving consistency.

- Energy Efficiency: NHF designs its machines to consume less energy, aligning with global sustainability goals.

- Scalability: NHF’s machines can be customized to handle various cable sizes and production volumes.

How NHF Is Revolutionizing Manufacturing

The impact of NHF’s cable stranding machines extends far beyond the manufacturing floor. By adopting NHF’s technology, companies can achieve faster production cycles, lower costs, and higher-quality products. This is particularly important in industries like telecommunications, where the demand for reliable and high-performance cables is skyrocketing.

For example, the rise of 5G networks has created an urgent need for advanced cables capable of handling high-speed data transmission. NHF’s cable stranding machines are specifically designed to produce cables that meet these stringent requirements. Similarly, the automotive industry relies on NHF technology to manufacture robust cables for electric vehicles, which require superior conductivity and durability.

Industry Applications and Benefits

NHF’s cable stranding machines are used in a variety of industries, each benefiting from the company’s innovative approach:

- Telecommunications: High-speed data cables for 5G networks and fiber optics.

- Automotive: Durable cables for electric vehicles and advanced driver-assistance systems (ADAS).

- Aerospace: Lightweight, high-performance cables for aircraft and spacecraft.

- Energy: Reliable cables for renewable energy systems like wind turbines and solar panels.

NHF’s Commitment to Sustainability

In addition to its technological innovations, NHF is committed to sustainability. The company designs its machines to minimize energy consumption and reduce material waste, supporting global efforts to combat climate change. By helping manufacturers produce eco-friendly cables, NHF is contributing to a greener future.

Moreover, NHF actively collaborates with industry partners to develop sustainable manufacturing practices. This includes the use of recyclable materials and the implementation of energy-efficient production methods. Such initiatives not only benefit the environment but also enhance the company’s reputation as a responsible and forward-thinking manufacturer.

Future Trends in Cable Manufacturing

The cable manufacturing industry is undergoing rapid transformation, driven by advancements in technology and increasing demand for high-performance cables. NHF is at the forefront of these changes, continually innovating to stay ahead of the curve.

One emerging trend is the integration of smart technologies into cable stranding machines. NHF is exploring the use of IoT-enabled sensors and AI algorithms to further improve machine performance and monitor production in real-time. These advancements will enable manufacturers to optimize their operations and respond quickly to market demands.

The Role of Cable Stranding Machine China in Global Manufacturing

China has become a global hub for cable manufacturing, thanks to companies like NHF. By exporting its state-of-the-art cable stranding machines, NHF is helping manufacturers worldwide enhance their capabilities. This not only strengthens China’s position in the global market but also fosters international collaboration and innovation.

Conclusion

Dongguan NHF Machinery Co., Ltd is revolutionizing the cable manufacturing industry through its innovative cable stranding machines. By combining precision engineering, automation, and sustainability, NHF is setting new standards for efficiency and quality. As industries continue to evolve, NHF’s technology will play an increasingly important role in meeting the demands of modern manufacturing.

Whether it’s supporting the growth of 5G networks, advancing electric vehicle production, or contributing to renewable energy solutions, NHF’s cable stranding machines are at the heart of these transformative changes. With a commitment to innovation and sustainability, NHF is not just shaping the future of cable manufacturing—it’s revolutionizing the entire industry.

Post time: Aug-18-2025