Introduction to Cable Stranding Machines

In the modern cable manufacturing industry, precision and efficiency are paramount. One of the most critical processes in cable production is stranding, where individual wires or conductors are twisted together to form a cohesive cable. At the forefront of this technological advancement is Dongguan NHF Machinery Co., Ltd, commonly known as NHF. With years of expertise and innovation, NHF has developed state-of-the-art cable stranding machines that are revolutionizing the industry.

In this article, we will explore how cable stranding machines, particularly those designed by NHF, enhance precision in cable making. Additionally, we’ll touch on the importance of high-speed cable stranding and the role of energy efficiency in modern manufacturing processes.

What Are Cable Stranding Machines?

Cable stranding machines are specialized equipment used to twist individual wires or conductors into a single, unified cable. This process not only improves the structural integrity of the cable but also enhances its electrical and mechanical properties. Stranded cables are widely used in industries such as telecommunications, power transmission, and automotive manufacturing.

NHF’s cable stranding machines are designed to meet the growing demand for high-quality cables. By leveraging advanced technology, these machines ensure uniform stranding, minimal material wastage, and optimal performance. The precision offered by NHF’s machines is unparalleled, making them a preferred choice for manufacturers worldwide.

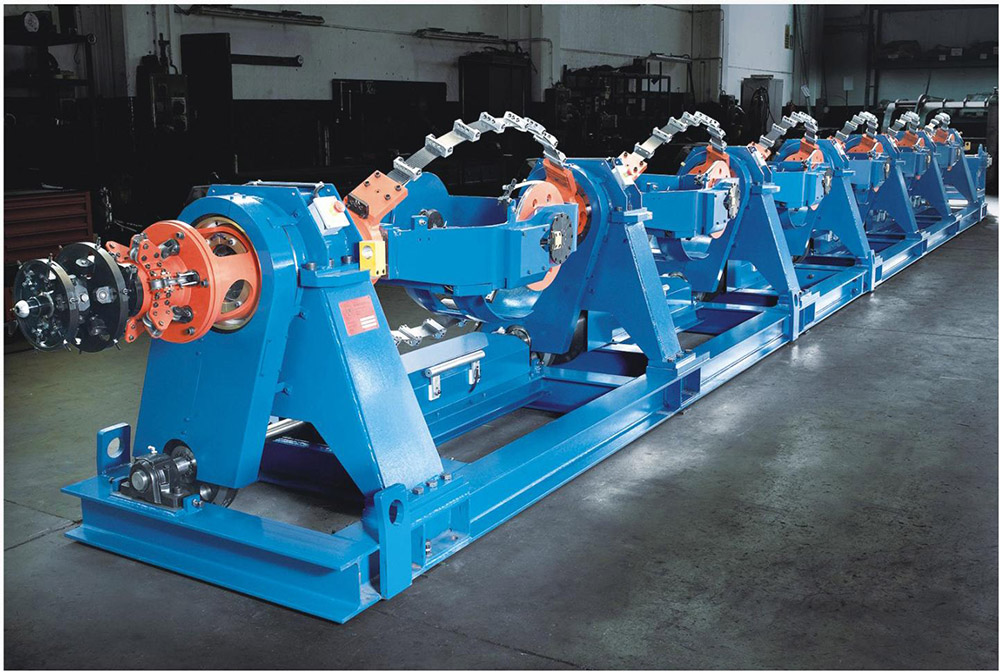

630P Stranding Machine

200P stranding machine

500P stranding machine

300P stranding machine

Key Features of NHF’s Cable Stranding Machines

NHF has consistently pushed the boundaries of innovation to deliver cutting-edge cable stranding machines. Some of the key features of their machines include:

- High-Speed Operation: NHF’s machines are designed for high-speed cable stranding, significantly reducing production time without compromising quality.

- Precision Engineering: Advanced control systems ensure accurate stranding, resulting in cables with consistent dimensions and properties.

- Energy Efficiency: NHF prioritizes energy efficiency, reducing operational costs and environmental impact.

- Durability: Built with robust materials, NHF’s machines are designed for long-term use, minimizing maintenance requirements.

- Customizability: NHF offers machines that can be tailored to meet specific manufacturing needs, ensuring maximum flexibility for clients.

How Cable Stranding Machines Improve Precision

Precision is a critical factor in cable manufacturing, as it directly impacts the performance and reliability of the final product. NHF’s cable stranding machines incorporate several advanced features that enhance precision:

- Advanced Tension Control: NHF’s machines are equipped with sophisticated tension control systems that ensure uniform stranding, eliminating inconsistencies in the cable structure.

- Real-Time Monitoring: Integrated sensors and monitoring systems provide real-time feedback, allowing operators to make adjustments on the fly.

- Automated Processes: Automation reduces the risk of human error, ensuring that each cable is manufactured to exact specifications.

- High-Speed Cable Stranding: The ability to operate at high speeds without sacrificing precision is a hallmark of NHF’s machines.

By incorporating these features, NHF’s cable stranding machines deliver unparalleled precision, meeting the stringent quality standards of today’s industries.

The Role of High-Speed Cable Stranding

In an era where time is money, high-speed cable stranding has become a necessity for manufacturers. NHF’s machines are designed to operate at high speeds, enabling manufacturers to meet tight deadlines without compromising on quality. This is particularly important in industries such as telecommunications, where the demand for high-performance cables continues to grow.

High-speed cable stranding not only improves productivity but also reduces operational costs. By completing production runs faster, manufacturers can allocate resources more efficiently, ultimately boosting profitability. NHF’s commitment to high-speed cable stranding ensures that their clients remain competitive in an ever-evolving market.

Energy Efficiency: A Sustainable Approach

As the world shifts towards sustainable manufacturing practices, energy efficiency has become a key consideration for manufacturers. NHF’s cable stranding machines are designed with energy efficiency in mind, reducing power consumption without compromising performance. This not only lowers operational costs but also minimizes the environmental impact of cable production.

Energy-efficient machines are particularly beneficial in large-scale manufacturing operations, where even small reductions in power consumption can lead to significant cost savings. NHF’s focus on sustainability aligns with the global push for greener manufacturing practices, making their machines a smart choice for environmentally conscious manufacturers.

Industry Applications of Stranded Cables

Stranded cables are used in a wide range of industries, each with its own unique requirements. Some of the most common applications include:

- Telecommunications: Stranded cables are used in the construction of telephone lines, fiber optic cables, and data transmission networks.

- Power Transmission: High-voltage power lines rely on stranded cables for their strength and conductivity.

- Automotive Manufacturing: Stranded cables are used in vehicle wiring systems, providing flexibility and durability.

- Construction: Stranded cables are commonly used in electrical installations for residential and commercial buildings.

NHF’s cable stranding machines are versatile enough to meet the demands of these diverse applications, making them a valuable asset for manufacturers across various industries.

Why Choose NHF for Cable Stranding Machines?

NHF has established itself as a leader in the cable manufacturing industry, thanks to its commitment to innovation and quality. Here are some reasons why manufacturers choose NHF for their cable stranding needs:

- Proven Track Record: With years of experience, NHF has a deep understanding of the challenges and requirements of cable manufacturing.

- Cutting-Edge Technology: NHF’s machines incorporate the latest advancements in engineering and automation.

- Customer Support: NHF provides comprehensive support, from machine installation to maintenance and training.

- Global Reach: NHF’s machines are used by manufacturers around the world, a testament to their quality and reliability.

Conclusion

Cable stranding machines play a crucial role in the production of high-quality cables, and NHF is at the forefront of this technological revolution. By offering machines that combine precision, efficiency, and sustainability, NHF empowers manufacturers to meet the demands of today’s competitive market.

Whether you’re looking to improve productivity, reduce costs, or enhance the quality of your cables, NHF’s cable stranding machines are the ideal solution. With a focus on high-speed cable stranding and energy efficiency, NHF continues to set new standards in the cable manufacturing industry.

Post time: Apr-25-2025