Dongguan NHF Machinery Co., Ltd (NHF) has long been recognized as a driving force in the evolution of mesh forming technology. As industries across the globe demand greater efficiency, precision, and reliability, NHF’s horizontal mesh forming machines stand out as a testament to the company’s commitment to innovation and quality. In this news feature, we explore the latest advancements in NHF’s horizontal mesh forming machine technology and its impact on industrial output, with a spotlight on the vital roles of wire mesh welding machine and automatic mesh panel welding machine solutions.

NHF’s Horizontal Mesh Forming Machine: A Game Changer

The horizontal mesh forming machine developed by NHF is engineered to meet the diverse needs of industries such as construction, automotive, agriculture, and security. Unlike traditional vertical systems, the horizontal design optimizes the production process, allowing for higher output rates, enhanced safety, and improved mesh consistency.

One of the standout features of NHF’s horizontal mesh forming machines is their ability to integrate seamlessly with other automation equipment. This integration is particularly valuable in facilities where maximizing throughput and minimizing manual intervention are top priorities.

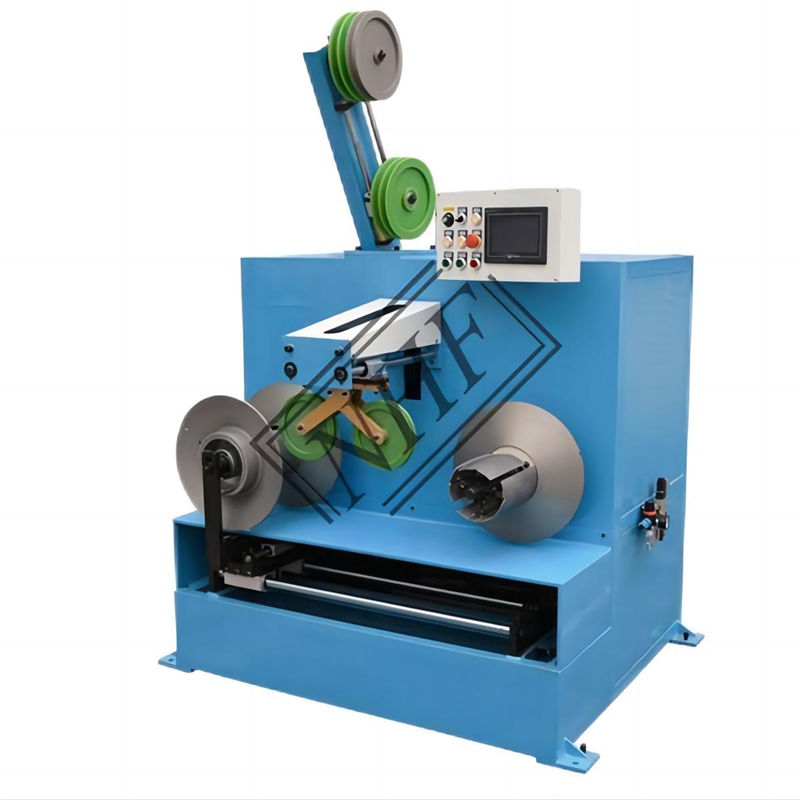

end shaft pay-off machine

630p double strander

copper wire laying frame

Key Advantages of NHF Horizontal Mesh Forming Machines

- High Precision: Advanced servo control systems enable precise wire positioning and welding, resulting in uniform mesh panels.

- Flexibility: Adjustable settings accommodate various mesh sizes and wire diameters, catering to different project requirements.

- Durability: Robust construction and high-quality materials ensure longevity and reliability, even under continuous operation.

- Cost-Effectiveness: Reduced labor costs and minimized material waste translate into significant savings for manufacturers.

Integrating Wire Mesh Welding Machine Technology

Wire mesh welding machine technology is at the heart of NHF’s horizontal mesh forming systems. These machines utilize state-of-the-art welding techniques to join intersecting wires with exceptional strength and accuracy. The result is a mesh panel that meets stringent industry standards for structural integrity and load-bearing capacity.

NHF’s wire mesh welding machines feature intelligent controls that monitor every stage of the welding process. This ensures consistent weld quality, reduces the likelihood of defects, and supports the production of high-performance mesh products for demanding applications like reinforced concrete, fencing, and industrial shelving.

Industry Trends: Automated Welding Solutions

The global shift toward automation in manufacturing has led to a surge in demand for sophisticated welding solutions. NHF’s wire mesh welding machines are designed to be compatible with both fully automated and semi-automated production lines, providing manufacturers with the flexibility to scale their operations and adapt to evolving market needs.

Automatic Mesh Panel Welding Machine: Redefining Efficiency

Another cornerstone of NHF’s technological portfolio is the automatic mesh panel welding machine. This equipment automates the entire process of mesh panel production, from wire feeding and straightening to cutting, welding, and stacking. The result is a streamlined workflow that significantly boosts productivity and reduces human error.

Automatic mesh panel welding machines from NHF are equipped with user-friendly interfaces and real-time diagnostics, enabling operators to monitor performance and address issues promptly. These features contribute to higher uptime and consistent product quality, which are essential in high-volume manufacturing environments.

Expanding Applications in Modern Industry

With the construction industry experiencing a boom in infrastructure projects worldwide, the demand for prefabricated mesh panels has never been higher. NHF’s automatic mesh panel welding machines empower manufacturers to meet this demand by delivering large quantities of customized mesh panels quickly and efficiently. Applications extend beyond construction to include transportation, agriculture, and even renewable energy sectors, where robust mesh products are essential for safety and performance.

Industry Insights: The Broader Impact of Mesh Forming Technology

The advancements pioneered by NHF in horizontal mesh forming technology have far-reaching implications for the industrial landscape. As sustainability becomes a key concern, efficient mesh forming processes help reduce material waste and energy consumption. Furthermore, the ability to produce high-strength, reliable mesh products supports the development of safer, more durable infrastructure and equipment.

According to recent industry reports, the global mesh welding machine market is projected to grow at a steady rate, driven by the adoption of automated solutions and increasing investments in smart manufacturing. NHF’s focus on research and development positions the company at the forefront of this growth, with a product lineup that addresses the evolving needs of manufacturers worldwide.

Collaborative Innovation and Future Outlook

NHF actively collaborates with industry partners, research institutions, and end-users to refine its technologies and anticipate future trends. This collaborative approach ensures that NHF’s horizontal mesh forming machines remain at the cutting edge, delivering value not just to customers but to the broader industrial ecosystem.

Conclusion: NHF’s Commitment to Excellence

Dongguan NHF Machinery Co., Ltd continues to set new benchmarks in horizontal mesh forming machine technology. By integrating advanced wire mesh welding machine and automatic mesh panel welding machine solutions, NHF empowers manufacturers to achieve superior industrial output, enhance product quality, and stay competitive in a rapidly evolving market. As industries worldwide seek smarter, more sustainable manufacturing solutions, NHF stands ready to lead the way with innovation, reliability, and a steadfast commitment to customer success.

Post time: Sep-30-2025