Introduction to NHF’s Expertise

Dongguan NHF Machinery Co., Ltd, abbreviated as NHF, has been a leading name in the manufacturing of high-performance machinery tailored for cable and wire industries. With years of expertise, NHF has developed innovative solutions to meet the diverse needs of customers in the cable manufacturing sector. Among its flagship products, the double twist bunching machine stands out as a versatile and efficient solution for handling varied cable specifications. This article explores the capabilities of NHF’s double twist bunching machine and its role in advancing cable production processes.

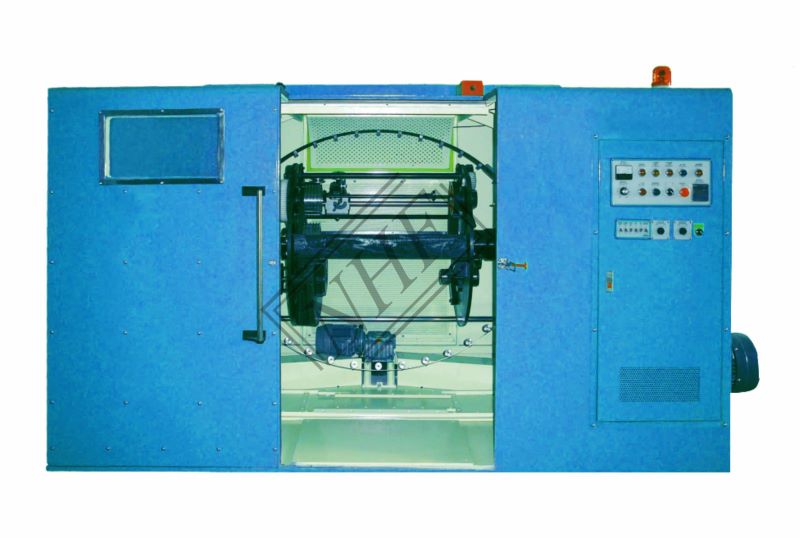

Understanding the Double Twist Bunching Machine

The double twist bunching machine is a specialized piece of equipment designed to twist multiple strands of wire or cable together at high speeds. NHF’s machine is engineered to handle a wide range of cable specifications, including copper wire bunching machine and cable bunching machine applications. With its precision and adaptability, this machine ensures uniform twisting, superior tensile strength, and optimized electrical conductivity for the final product.

NHF’s double twist bunching machine is equipped with advanced features such as programmable control systems, high-speed operation, and energy-efficient motors. These features make it suitable for industries requiring consistent output, whether for small-scale or large-scale cable production.

Key Features of NHF’s Double Twist Bunching Machine

NHF’s double twist bunching machine is designed with a range of features that enhance its versatility and performance:

- Wide Compatibility: The machine can handle various cable specifications, including copper wires, aluminum wires, and mixed-material cables.

- High-Speed Performance: With advanced motor systems, the machine can achieve high rotational speeds, ensuring efficient production cycles.

- Precision Control: NHF incorporates programmable logic controllers (PLCs) for precise control over twisting parameters, ensuring uniformity and quality.

- Durability: Built with robust materials, the machine guarantees long-term reliability and reduced maintenance costs.

- Energy Efficiency: NHF’s focus on sustainability ensures that the machine operates with minimal energy consumption.

Applications in Copper Wire Bunching Machine and Cable Bunching Machine Processes

The double twist bunching machine plays a pivotal role in copper wire bunching machine operations. Copper wires, known for their excellent electrical conductivity, require precise bunching to maintain their performance characteristics. NHF’s machine ensures that copper wires are twisted uniformly, reducing resistance and enhancing strength. Additionally, the machine excels in cable bunching machine applications, where diverse cable specifications need to be handled with precision and speed.

NHF’s double twist bunching machine is ideal for industries manufacturing power cables, communication cables, and specialty cables. Its ability to adapt to different material types and dimensions makes it a versatile choice for cable manufacturers worldwide.

Why Choose NHF for Your Cable Manufacturing Needs?

NHF has established itself as a trusted name in the machinery industry, offering cutting-edge solutions for cable and wire production. Here are some reasons why NHF stands out:

- Innovative Technology: NHF invests heavily in research and development to deliver state-of-the-art machinery that meets evolving industry demands.

- Customizable Solutions: NHF understands that every customer has unique requirements, and its machines can be tailored to specific production needs.

- Global Reach: NHF serves customers across the globe, ensuring reliable support and service wherever you are.

- Commitment to Quality: NHF’s machines undergo rigorous testing to ensure they meet the highest standards of performance and durability.

Industry Trends and the Role of Advanced Machinery

The cable and wire manufacturing industry is evolving rapidly, driven by technological advancements and increasing demand for high-performance cables. As industries such as telecommunications, automotive, and renewable energy expand, the need for reliable and efficient cable manufacturing solutions grows. NHF’s double twist bunching machine is a testament to how advanced machinery can address these challenges.

One notable trend is the shift towards sustainable manufacturing practices. NHF aligns with this trend by designing energy-efficient machines that reduce environmental impact. Additionally, the integration of smart technologies like IoT and AI in cable manufacturing machinery is paving the way for greater automation and precision.

Conclusion

NHF’s double twist bunching machine is a versatile and reliable solution for handling diverse cable specifications. Whether you’re working with copper wire bunching machine or cable bunching machine processes, NHF’s equipment ensures superior performance, efficiency, and adaptability. As the cable manufacturing industry continues to evolve, NHF remains committed to providing innovative machinery that meets the needs of its customers.

If you’re looking for a trusted partner in cable manufacturing machinery, Dongguan NHF Machinery Co., Ltd is your go-to choice. With its expertise, dedication to quality, and focus on customer satisfaction, NHF is poised to help you achieve your production goals.

Tags:Wrapping Machine,Double Strander

Post time: Apr-24-2025