In the ever-evolving world of cable manufacturing and electrical automation, Dongguan NHF Machinery Co., Ltd (NHF) stands out as a leader in providing innovative solutions. With the increasing demand for efficiency, precision, and automation, NHF has developed state-of-the-art machinery like the cable tapping machine and copper wire wrapping machine, which are transforming the way manufacturers approach cable production. This article explores NHF’s latest advancements, industry trends, and how their solutions are setting new benchmarks in the automation sector.

NHF: Pioneering Automation in Cable Manufacturing

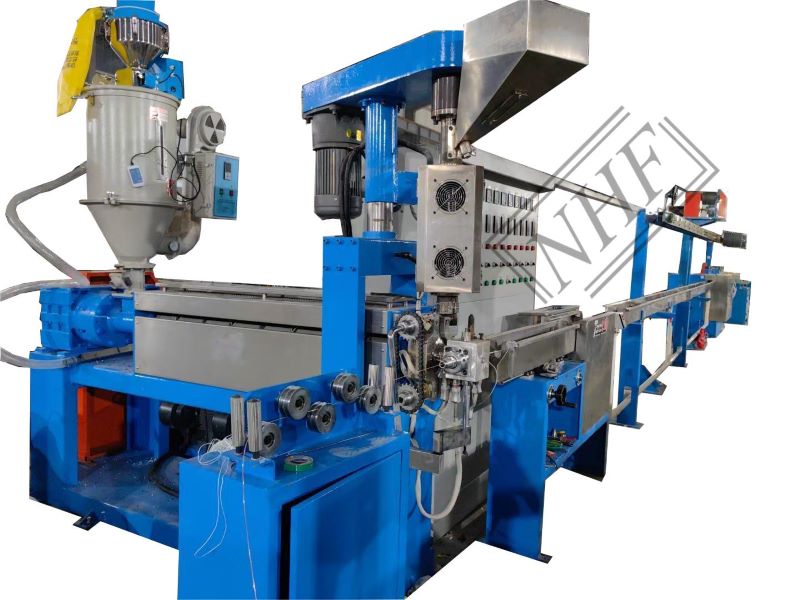

Dongguan NHF Machinery Co., Ltd, widely recognized as NHF, has been at the forefront of cable processing machinery for years. Their commitment to research and development has resulted in a comprehensive portfolio of automation equipment, including the highly sought-after cable tapping machine and copper wire wrapping machine. These machines are designed to streamline the production process, reduce manual labor, and ensure superior product quality.

The cable tapping machine, in particular, has become a staple in modern wire and cable workshops. It automates the process of wrapping tapes around cables, ensuring uniformity and tightness, which are essential for electrical insulation and protection. Meanwhile, the copper wire wrapping machine is engineered for high-speed and precise wrapping of copper wires, which is crucial for manufacturing high-performance cables used in electronics, automotive, and power transmission industries.

Latest Developments and Product Features

NHF’s latest line of cable tapping machines incorporates advanced features such as programmable logic controllers (PLC), touch screen interfaces, and automatic tension control. These upgrades allow operators to easily set parameters, monitor progress, and maintain consistent quality throughout the production run. The machines are also equipped with safety mechanisms to prevent accidents and ensure operator wellbeing.

Similarly, the copper wire wrapping machines from NHF are designed for flexibility and speed. They can handle a wide range of wire diameters and wrapping materials, making them suitable for both standard and custom cable production. The precision-driven motors and real-time monitoring systems guarantee that each wire is wrapped to exact specifications, reducing material waste and enhancing overall productivity.

Industry Trends: Automation and Smart Manufacturing

The cable manufacturing industry is undergoing a significant transformation, driven by the global push towards automation and smart manufacturing. Companies are increasingly investing in automated solutions like cable tapping machines and copper wire wrapping machines to stay competitive and meet the growing demand for high-quality cables.

- Quality Assurance: Automated machines ensure consistent wrapping and insulation, reducing the risk of defects and improving product reliability.

- Labor Efficiency: Automation reduces the need for manual handling, allowing manufacturers to allocate human resources to more value-added tasks.

- Cost Savings: By minimizing material waste and optimizing production speeds, companies can achieve significant cost reductions.

- Data Integration: Modern machines are equipped with IoT capabilities, enabling real-time data collection and process optimization.

NHF is at the center of this technological shift, continuously upgrading their machinery to incorporate the latest advancements in automation, robotics, and digital integration. Their solutions are not only enhancing the efficiency of cable production but also setting new industry standards for safety and sustainability.

Application Scenarios and Customer Success

NHF’s cable tapping machines and copper wire wrapping machines are widely used across various sectors, including telecommunications, automotive, aerospace, and renewable energy. Customers have reported significant improvements in production throughput, product consistency, and operational flexibility after integrating NHF’s equipment into their manufacturing lines.

| Industry | Application | NHF Solution |

|---|---|---|

| Telecommunications | Data & Signal Cable Production | Cable Tapping Machine |

| Automotive | Wire Harness Manufacturing | Copper Wire Wrapping Machine |

| Energy | Power Cable Insulation | Cable Tapping Machine |

| Electronics | Flexible Cable Assembly | Copper Wire Wrapping Machine |

Why Choose NHF for Your Automation Needs?

NHF’s reputation is built on a foundation of technical expertise, customer-centric service, and relentless innovation. Their team of engineers works closely with clients to understand their unique requirements and deliver tailored solutions that maximize productivity and ROI.

- Comprehensive after-sales support and training

- Customizable machine configurations

- Strict quality control and certification

- Global delivery and service network

With NHF’s cable tapping machine and copper wire wrapping machine, manufacturers can confidently embrace the future of automated cable production. These machines not only improve operational efficiency but also contribute to a safer, more sustainable, and more competitive manufacturing environment.

Looking Ahead: The Future of Cable Manufacturing

As the industry continues to evolve, NHF remains committed to leading the charge in automation technology. Their ongoing investment in R&D ensures that their machines are always at the cutting edge, ready to meet the challenges of tomorrow’s cable manufacturing landscape.

For companies seeking to enhance their automation capabilities, NHF offers a comprehensive suite of solutions that deliver tangible results. Whether you are looking to upgrade your existing production line or invest in new equipment, NHF’s cable tapping machine and copper wire wrapping machine are proven choices for quality, reliability, and innovation.

Tags:Coiling Machine,wrapping machine

Post time: Aug-11-2025