introduction: As an important part of power transmission and communication, wire and cable are essential to learn and understand the basics of wire and cable. This article will start from the basic concept of wires, the distinction between wires and cables and a brief introduction to structure, the requirements of copper wires, the insulation sheath and jacket, the color definition of wires, the classification of wires, the meaning of printing on wires, the wire gauge and the corresponding loading Delve into the basics of wire and cable in terms of flow, inspection, testing and standards.

1. The basic concept of wires: Wires are conductors used to transmit electric current and are generally made of metal materials such as copper or aluminum. It usually consists of a center conductor, wrapped in insulation to stop current leakage and direct contact with other objects. The outer sheath is used to protect the insulation layer from external physical and chemical damage.

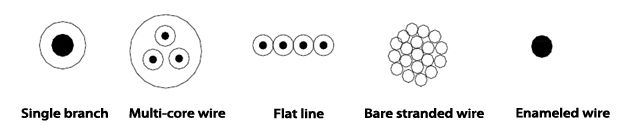

Detailed introduction: The center conductor of the wire can be a solid conductor (such as solid copper wire) or a stranded conductor (such as stranded copper wire). Solid conductors are suitable for low-frequency circuits and shorter distance transmissions, while stranded conductors are suitable for high-frequency circuits and long-distance transmissions. The material of the insulating layer can be selected according to specific requirements, such as polyvinyl chloride (PVC), polyethylene (PE) or cross-linked polyethylene (XLPE).

2.The distinction and structure of wires and cables:

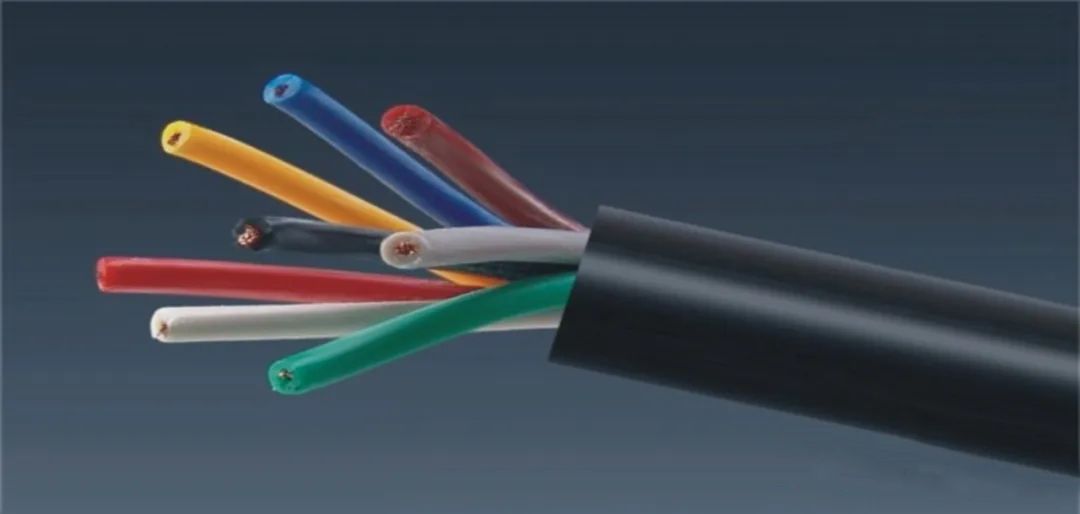

2.1 Distinction: The wire is usually a single core with only one center conductor and insulation. The cable is composed of multi-core wires, each core wire has its own insulation layer, as well as the overall insulation layer and outer sheath.

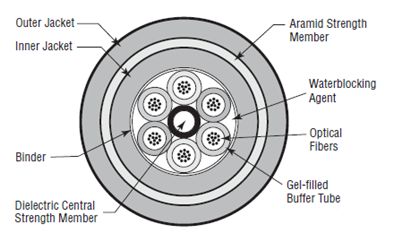

Detailed introduction: Cables are both functional and complex and are suitable for multi-core transmission and long-distance power transmission. The structure of the cable includes not only the center conductor and the insulation layer, but also the filler, the shielding layer, the insulation sheath and the outer sheath. Fillers are used to maintain a stable spacing between core wires. The shielding layer is used to isolate the interference between the core wires. The insulating sheath is used to protect the overall insulation layer, while the outer sheath is used to protect the insulation layer from external physical and chemical damage.

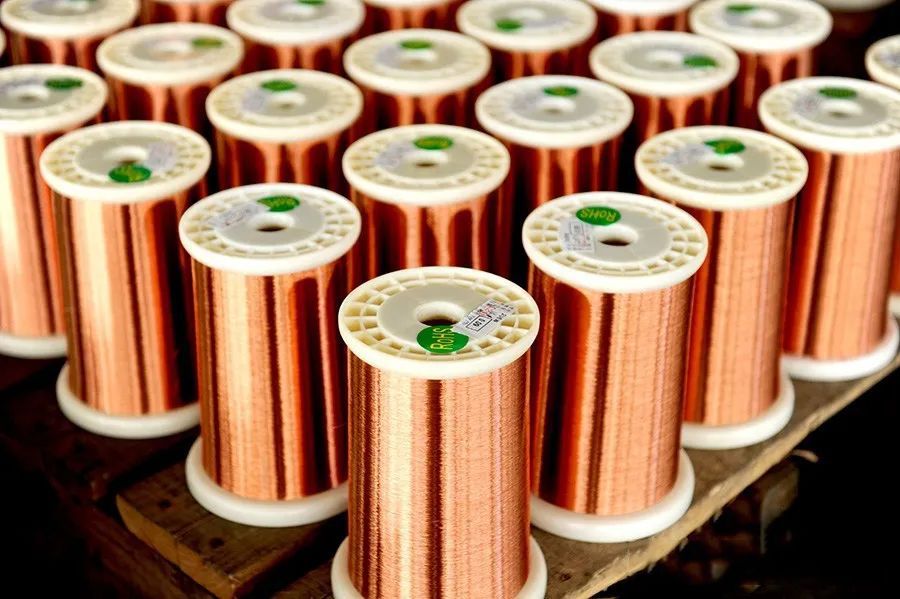

3. Requirements for copper wire: As a commonly used conductor material, copper wire requires high conductivity. In addition to electrical conductivity, copper wire must also have good thermal conductivity, tensile strength and corrosion resistance.

Detailed introduction: As a conductor material, copper has low electrical resistance, high electrical conductivity and good thermal conductivity. High-purity copper wire can provide better conductivity. In addition, copper needs to have sufficient tensile strength and corrosion resistance to ensure the longevity and reliability of the wire.

4. Insulation sheath and jacket: The insulating layer is used to prevent current leakage and direct contact with other objects. Commonly used insulating materials are polyvinyl chloride (PVC), polyethylene (PE) and cross-linked polyethylene (XLPE). The outer sheath is used to protect the insulating layer from external physical and chemical damage, and the commonly used materials are polyvinyl chloride (PVC) or polyethylene (PE).

Detailed introduction: The insulation layer is an important part of the insulation and protection of wires and cables. Different insulation materials have different requirements for different application scenarios. Polyvinyl chloride (PVC) insulation, for example, has good electrical properties and chemical resistance and is suitable for power transmission in homes and commercial buildings. The polyethylene (PE) insulation layer has good cold resistance and is widely used in outdoor power transmission. The cross-linked polyethylene (XLPE) insulation layer has better high temperature resistance and is suitable for power transmission in high temperature environments.

5. the color definition of the wire: In wires and cables, wires of different colors represent different uses and voltage levels. For example, in the International Electrotechnical Commission (IEC) standard, blue represents the neutral wire, yellow-green represents the ground wire, and red or brown represents the phase wire.

Detailed introduction: The color definition of wires is basically consistent internationally and is used to distinguish different circuits and functions. For example, blue usually indicates the neutral wire, the path for return current. Yellow-green usually indicates a ground wire, which is used to conduct electrical current safely. Red or brown is usually used as the phase wire, which is responsible for carrying the current. Different countries and regions may have slight differences, so you need to understand local standards and regulations.

6. Classification of wire rods: Wires can be classified according to electrical properties, insulating materials, flame retardant properties, etc. Common classifications include low voltage (withstand voltage less than 1000V) cables, medium and high voltage cables, flame retardant cables, etc.

Detailed introduction: Classification of wires is based on different properties and application requirements. Low-voltage cables are suitable for home and commercial buildings, and generally withstand voltages below 1000V. Medium and high voltage cables are suitable for transmission lines, and the withstand voltage range is usually between 1kV and 500kV. Flame-retardant cables have good flame-retardant properties and prevent fire from spreading.

7. the meaning of wire printing: The printing on the wire is to identify the specific information of the wire, such as manufacturer, model, specification, voltage level, etc. This information is critical for the proper installation, use and maintenance of cables.

Detailed introduction: The printing on the wire is a mark added by the manufacturer during the manufacturing process to track and confirm the specific information of the wire. Through printing, users can determine the quality, specification and applicable environment of the wire. For example, the manufacturer's name and contact information can help users with after-sales service and technical support.

8. Wire gauge and corresponding ampacity: Wire gauge refers to the specification and diameter of the wire. Wires of different specifications have different load-carrying capacities and corresponding carrying capacities, which need to be selected according to specific needs.

Detailed introduction: Wire gauge is usually represented by a standard, such as AWG specification (American Wire Gauge), square millimeter (mm²) specification. Wires of different specifications have different cross-sectional areas and electrical conductivity, so the corresponding current carrying capacity will also be different. According to the current load and the length of the wire, the appropriate wire gauge can be selected to ensure the safe operation of the wire.

9. inspection, testing, standard description: In order to ensure that the wire meets the requirements of safety and reliability, the wire needs to undergo strict inspection and testing. Usually, the manufacture and use of wire rods need to comply with relevant national or international standards, such as IEC, GB and other standards.

Detailed introduction: Quality control of wire requires inspection and testing. For example, aspects such as conductor resistance, electrical insulation strength, durability of insulating layers, and tensile strength of conductive materials need to be tested. In addition, manufacturers and users need to comply with national or international standards, such as IEC, GB, etc., to ensure that the wire meets the relevant safety requirements and technical specifications.

in conclusion: The basic knowledge of wire and cable is essential for the correct use and maintenance of wire and cable. By understanding the basic concepts of wires, the distinction between wires and cables, the requirements of copper wires, insulation sheaths and jackets, the definition of wire colors, the introduction of wire classification, the meaning of wire printing, wire gauge and corresponding current carrying capacity and inspection, With the knowledge of testing and standards, we can better understand and apply wire and cable. I hope this article will be helpful to readers and enhance the professional knowledge of wire and cable.

E-mail: francesgu1225@hotmail.com

E-mail: francesgu1225@gmail.com

WhatsAPP: +8618689452274

Post time: Jul-21-2023